PrintSafe is the UK agent for Koenig & Bauer Coding. We support manufacturing and packing companies throughout the UK and Ireland with high-quality batch coding machines and aftersales support.

- Inkjet printers, hot foil coders and carton coding machines

- Print batch codes, lot codes, dates, unique codes and barcodes

- Free technical help desk

- Engineer and operator training

Continuous Inkjet Printers (CIJ)

Continuous inkjet (CIJ) is an established, and versatile, technology for batch code printing across food, FMCG, and other manufacturing industries. CIJ offers high-speed printing, excellent print adhesion and reliability over long hours of operation. The extensive range of standard, coloured and specialist inks means that you can print on nearly any substrate and in the toughest of production environments. As well as standard black or coloured inks, you can also print with thermochromic (colour-change) inks, sterilisation-resistant inks, low VOC inks and even UV-fluorescing ink for internal traceability.

Setting up your ‘messages’ or ‘labels’ is simple with pre-programmed formats, customisable layouts. You can create and store 100s of messages and the flexible password protection system can control user access to prevent unauthorised changes being made to your date codes.

If your coding takes place in a refrigerated environment, the heated print head in our alphaJET continuous inkjet printers maintains consistent print quality by minimising the impact of the temperature on the ink.

Thermal Inkjet Printers (TIJ)

Thermal inkjet (TIJ) is a cartridge-based alternative to CIJ for high-resolution coding onto food packaging, FMCG packaging, pharmaceutical cartons and directly onto some manufactured products. The growing range of available inks mean that TIJ is now suitable for printing onto a wider variety of substrates, including plastic, foil, film and metal.

With a similar touchscreen menu system to alphaJET CIJ printers, the betaJET verso TIJ gives you lots of flexibility for creating and storing print messages. For alphanumeric batch code printing, you would typically need just one print head, but you can add additional print heads for also printing bar codes, 2D codes or more detailed product information.

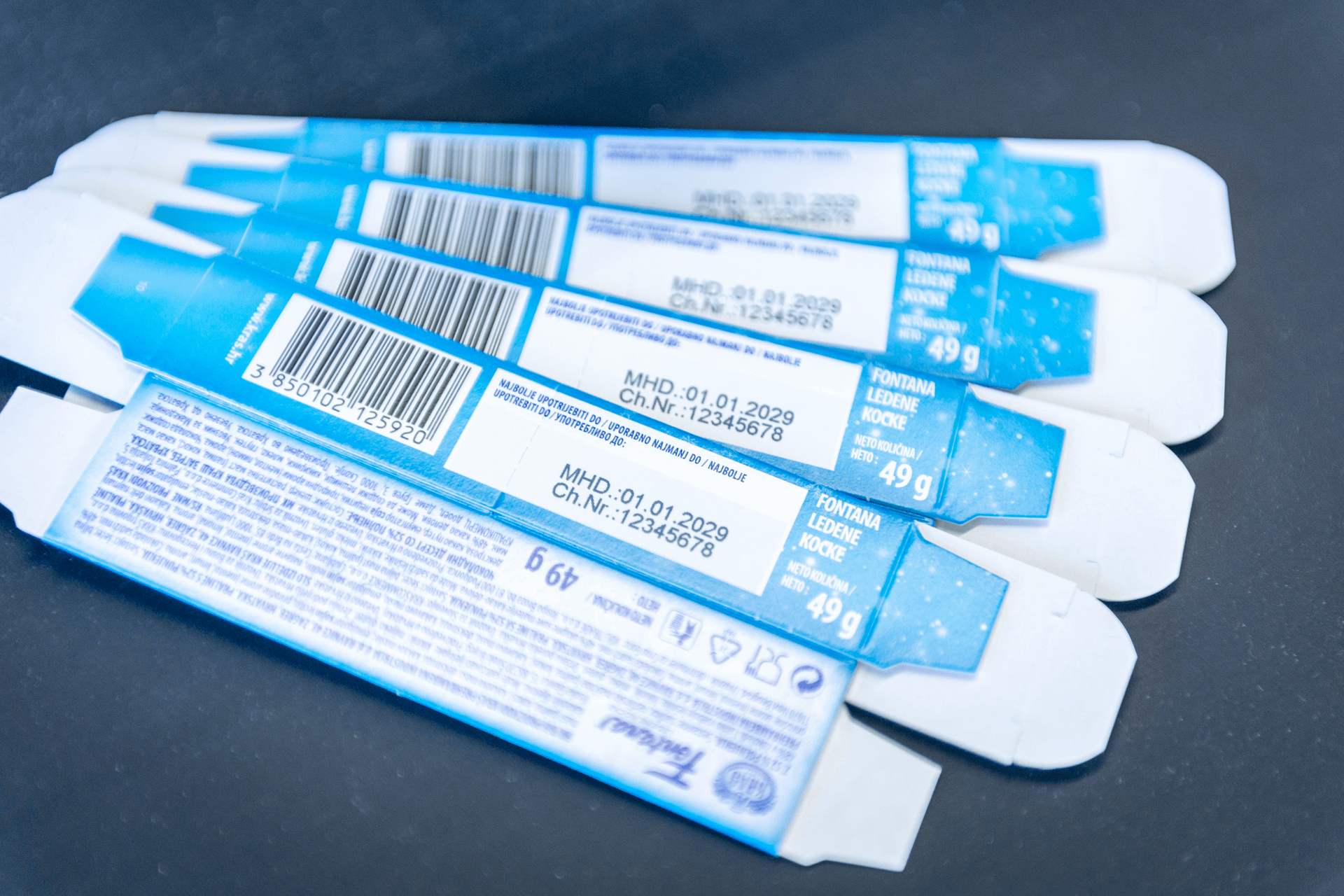

Sleeve & Carton Feeder for Batch Code and Lot Code Printing on Sleeves, Cartons and Pouches

A sleeve and carton feeder (you can also feed pouches or other flat-form packs) gives you a way to print batch codes and date codes quickly and accurately away from main production.

Throughput depends on pack size but you can expect to be able to code around 150-200 packs per minute, with reliably accurate print placement.

udaFORMAXX sleeve and carton feeders are designed to accommodate more than one printer, printer and vision system or even a label applicator. Some manufacturers use the standalone machines for printing codes and applying a label in one pass.