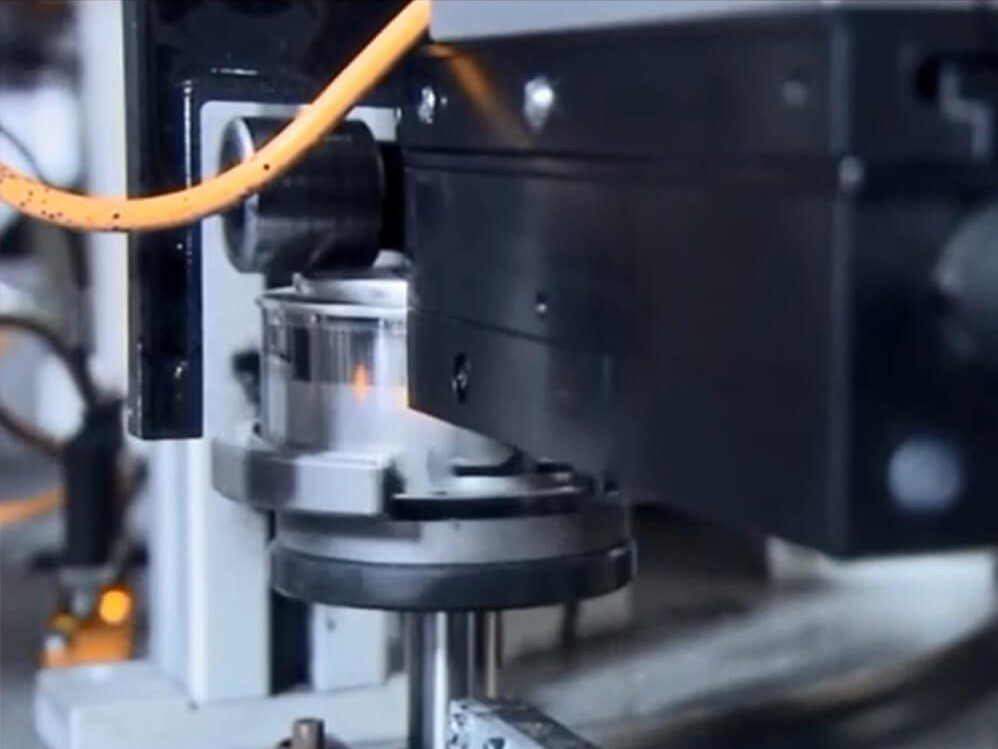

While there are a number of print and etching technologies available, the majority of the direct part marking projects that we work on are for continuous inkjet.

With continuous inkjet printing, you can print directly on almost any substrate – even where the surface is curved or uneven. You can also print in a selection of opaque colours for maximum contrast. UV curable inks and fuel-resistant inks can be used for parts and components that are subject to exposure to chemicals. There are also inks available for surface-treated metal.

alphaJET Continuous Inkjets for Part Marking

- Print a combination of machine and human readable data

- Variety of black and opaque coloured inks

- Multiple connectivity options for integration with production equipment

- Print high quality linear bar codes and 2D Datamatrix codes for part traceability

- Wide range of process-specific inks available (including UV fluorescing; fuel resistant; wash-off)

Printing Machine Readable Part Codes

Electronically generated codes let you print part-specific information in a simple format for reliable verification and part traceability. These can be in a 1D linear bar code or 2D data matrix code.

Manufacturers are increasingly using 2D data matrix codes because of the ability to encode a larger amount of data. It is also a more robust coding format; datamatrix codes are readable in any orientation and there is no risk of misreading.