If you are looking for a date or batch code printing machine, you might need help deciding which is the most suitable print technology for your product. Choosing the printer will ensure that date or batch coding fits seamlessly within your production process. Read on to understand the different options available from PrintSafe.

Continuous Inkjet Printing (CIJ)

Continuous inkjet (CIJ) is an established, and versatile, technology for date and batch code printing across food, FMCG, and other manufacturing industries. CIJ offers high-speed printing, excellent print adhesion and reliability over long hours of operation. The extensive range of standard, coloured and specialist inks means that you can print on nearly any substrate and in the toughest of production environments. As well as standard black or coloured inks, you can also print with thermochromic (colour-change) inks, sterilisation-resistant inks, low VOC inks and even food-safe inks for when the print comes into direct contact with your product.

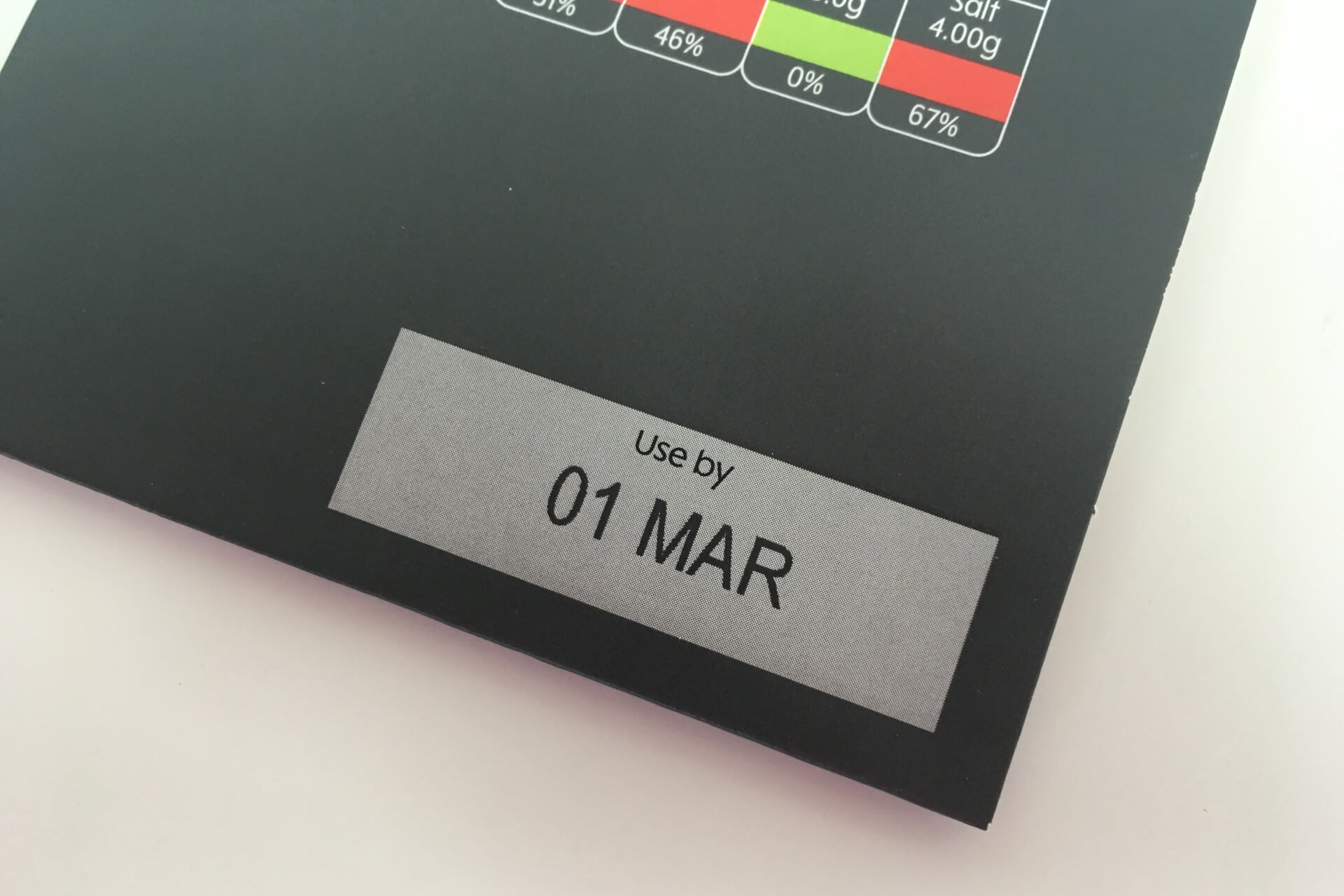

Setting up your date code ‘messages’ or ‘labels’ can be made easy by creating pre-programmed formats, customisable layouts and automatic Use By or Best Before date calculations. You can create and store 100s of messages and the flexible password protection system can control user access to prevent unauthorised changes being made to your date codes.

If your coding takes place in a refrigerated environment, the heated print head in our alphaJET continuous inkjet printers maintains consistent print quality by minimising the impact of the temperature on the ink.

Thermal Inkjet Printing (TIJ)

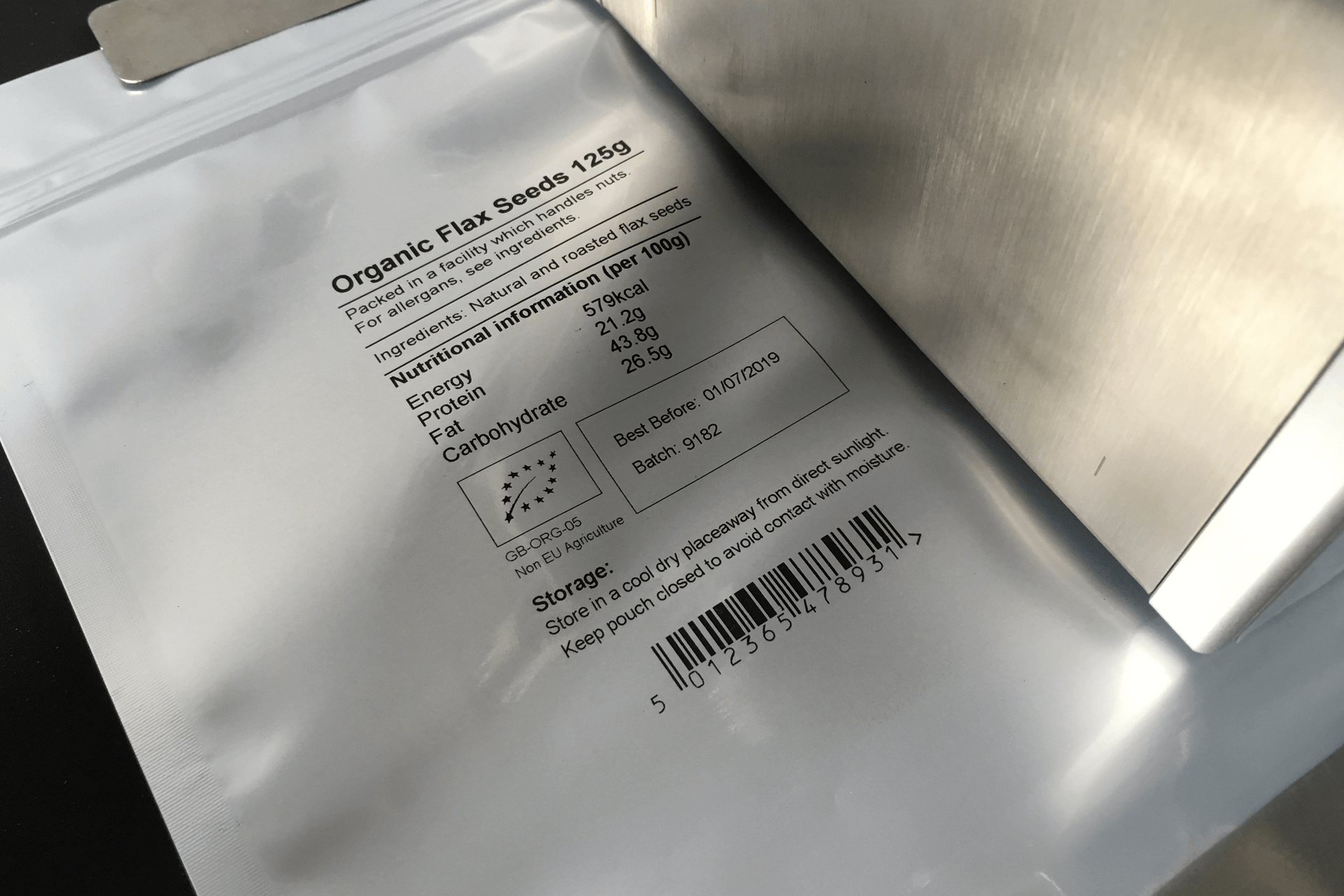

Thermal inkjet (TIJ) is a cartridge-based alternative to CIJ for high-resolution coding onto food packaging, FMCG packaging and directly onto some manufactured products. The growing range of available inks mean that TIJ is now suitable for printing onto a wider variety of substrates, including plastic, foil, film and metal.

With a similar touchscreen menu system to alphaJET CIJ printers, the betaJET verso TIJ gives you lots of flexibility for creating and storing date code messages. For date code printing, you would typically need just one print head, but you can add additional print heads for also printing bar codes, 2D codes or more detailed product information.

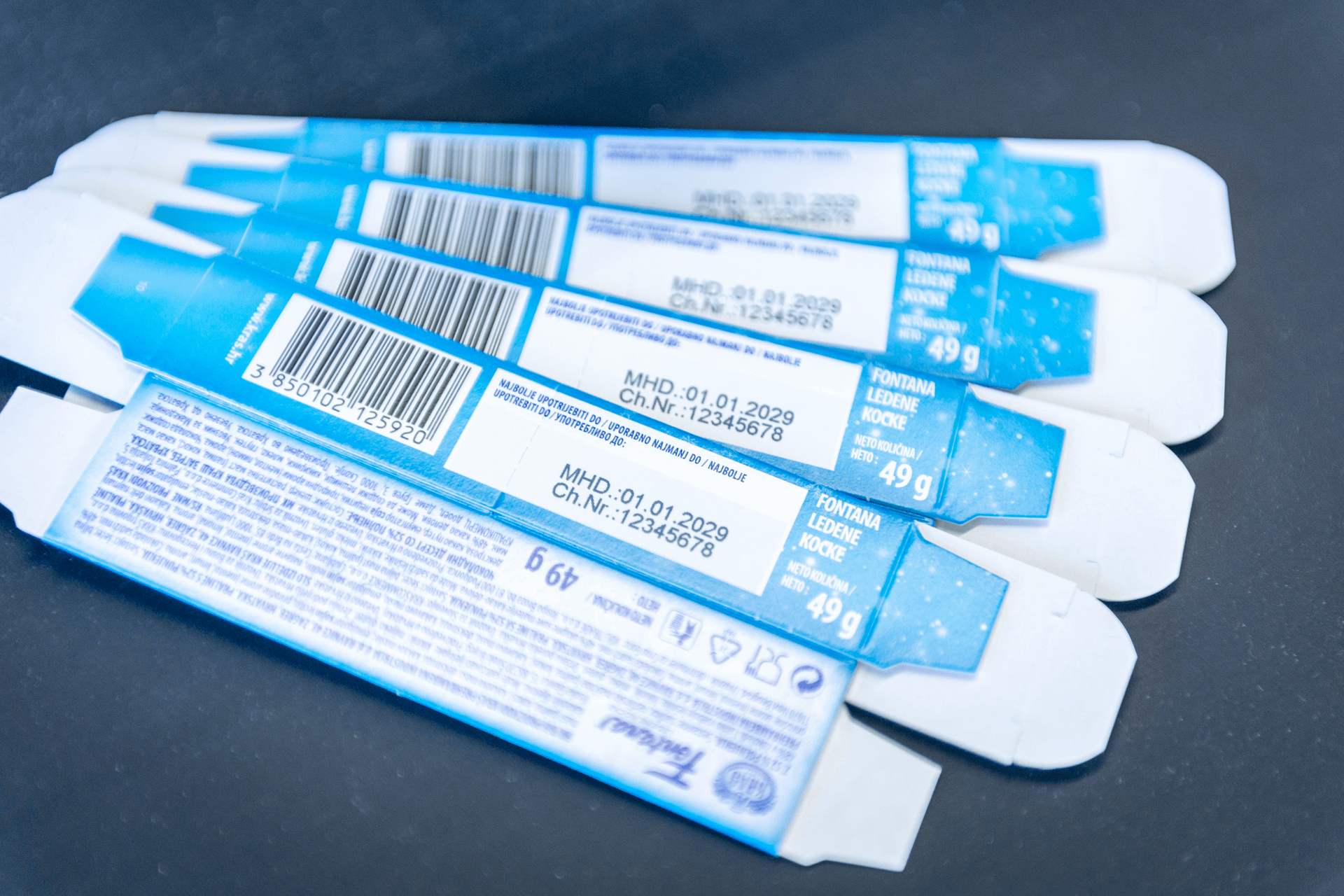

You can install a thermal inkjet printer on your conveyor or in other packaging machinery. It is also the most popular printer choice for use with our sleeve and carton coding machines, for accurate date, batch or barcode print placement on flat-form packaging.

Thermal Transfer Overprinting (TTO)

Thermal transfer printers are ideal for printing onto flexible packaging or labels, often integrated into flow-wrapping machinery. The ribbon-based printing gives you a bold high-resolution code. An advantage of thermal transfer is that you can print a larger amount of information, with the bigger print area. As well as printing error-free date codes you can also print barcodes, graphics and ingredients details.

There are a number of different ribbon types available for different coloured print or adhesion on trickier substrates.

We can supply our sleeve and carton feeding machines with a thermal transfer printer for date code, linear barcode and 2D code printing on flat-form packaging (sleeves, cartons, pouches).

Sleeve and Carton Coding

A sleeve and carton feeder (you can also feed pouches or other flat-form packs) gives you a way to print date codes quickly and accurately away from main production. Some of the biggest food manufacturing companies in the UK, use our carton feeding machines for accurate date-coding on cardboard sleeves for ready meal or other prepared food packs. Equally, carton feeders give you a way to automate date coding if you have not yet got other automation in place.

Throughput depends on pack size but you can expect to be able to code around 150-200 packs per minute, with reliably accurate print placement.

udaFORMAXX sleeve and carton feeders are designed to accommodate more than one printer, printer and vision system or even a label applicator. Some manufacturers use the standalone machines for printing a date code and applying a label in one pass.